Role: Industrial Design, DFM, Prototyping, Manufacturing Development

Focus: Tolerance tuning, magnet actuation, assembly reliability, CMF refinement

Contributions: Industrial design, Mechanical Desgin, DFM, Prototyping, Sourcing, Manufacturing

Focus: Tolerance tuning, magnet actuation, assembly reliability, CMF refinement

Contributions: Industrial design, Mechanical Desgin, DFM, Prototyping, Sourcing, Manufacturing

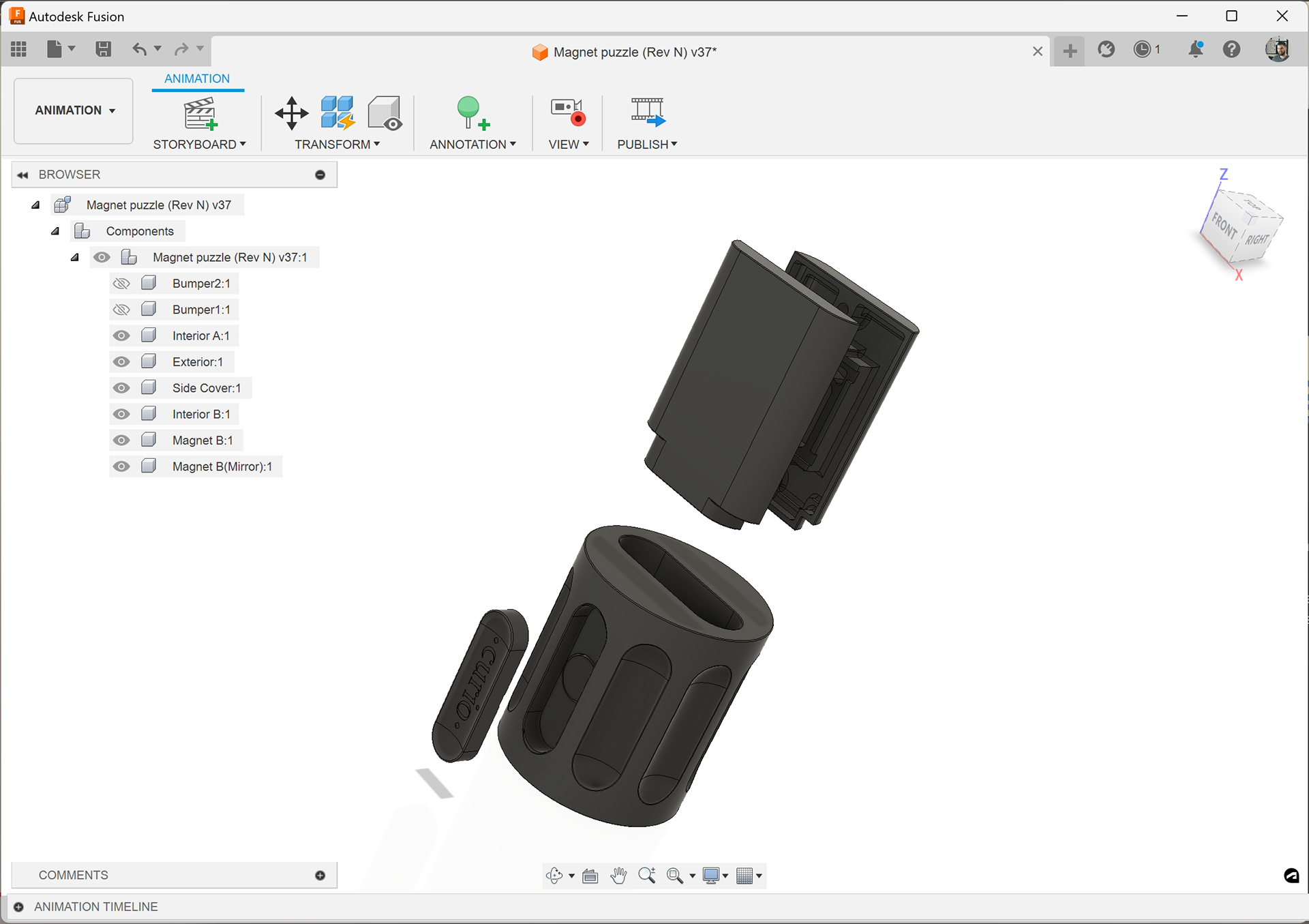

The Column is a two-part mechanical puzzle designed to feel impossibly simple on the outside while hiding a precise internal latch with no visible moving parts. The challenge was to design a mechanism that feels magical, manufacturable at scale, and durable in repeated use — all inside a clean cylindrical form.

The first prototypes were minimal and smooth, but the simplicity worked against the experience — the object lacked identity and offered no tactile landmarks. Drawing inspiration from architectural columns, I introduced fluting that added character, guided hand placement, and concealed assembly seams without revealing how the mechanism works.

These flues don't just add visual interest, we place them precisely to conceal and distract from parting lines that could give hinds as to how the puzzle is assembled.

How It works

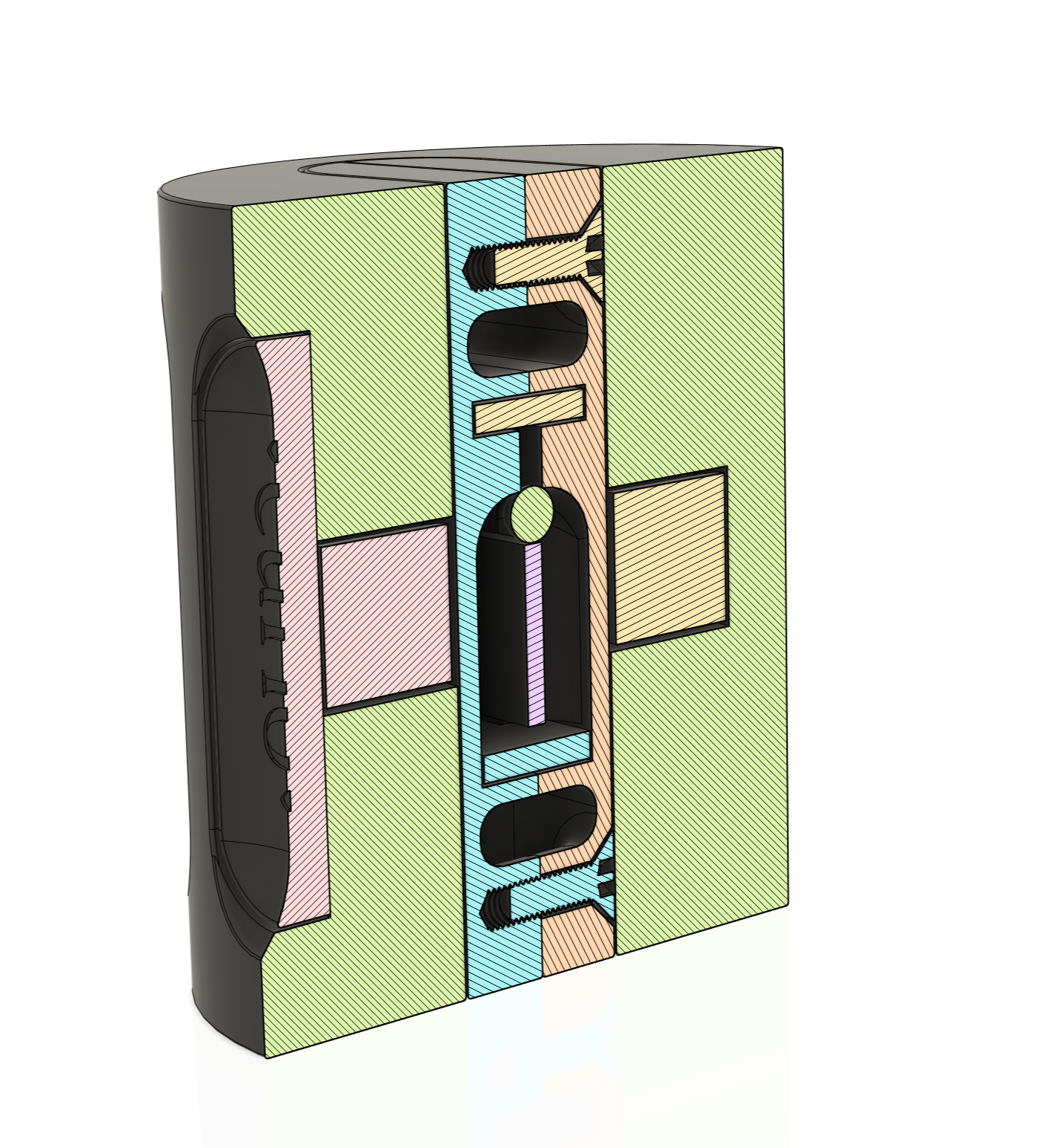

In side the shuttle there is a magnet that slides back and forth. We use the magnetic files to repel and attract the parts; this is what creates the "latch" holding the shuttle in place without visible interface between the parts. Once the internal magnet is below the external magnets the fields repel it pressing it down and retaining the shuttle.

The trick is that you can only make that happen by placing a small plastic ball bearing in the way of the internal magnets slide path. This requires you to invert the puzzles orientation and carefully place the column on top of the shuttle; forcing the internal shuttle magnet into place and latching the shuttle.

Once we nailed down the form we wanted and had the mechanism dialed in we ordered final production samples and made a terrible discovery. The adhesive backed foam bumpers we had used to stop the internal magnets from slamming into the top and bottom of the internals were not strong enough. The magnet would peel away the foam and get stuck on the adhesive left behind, rendering the puzzle unsolvable.

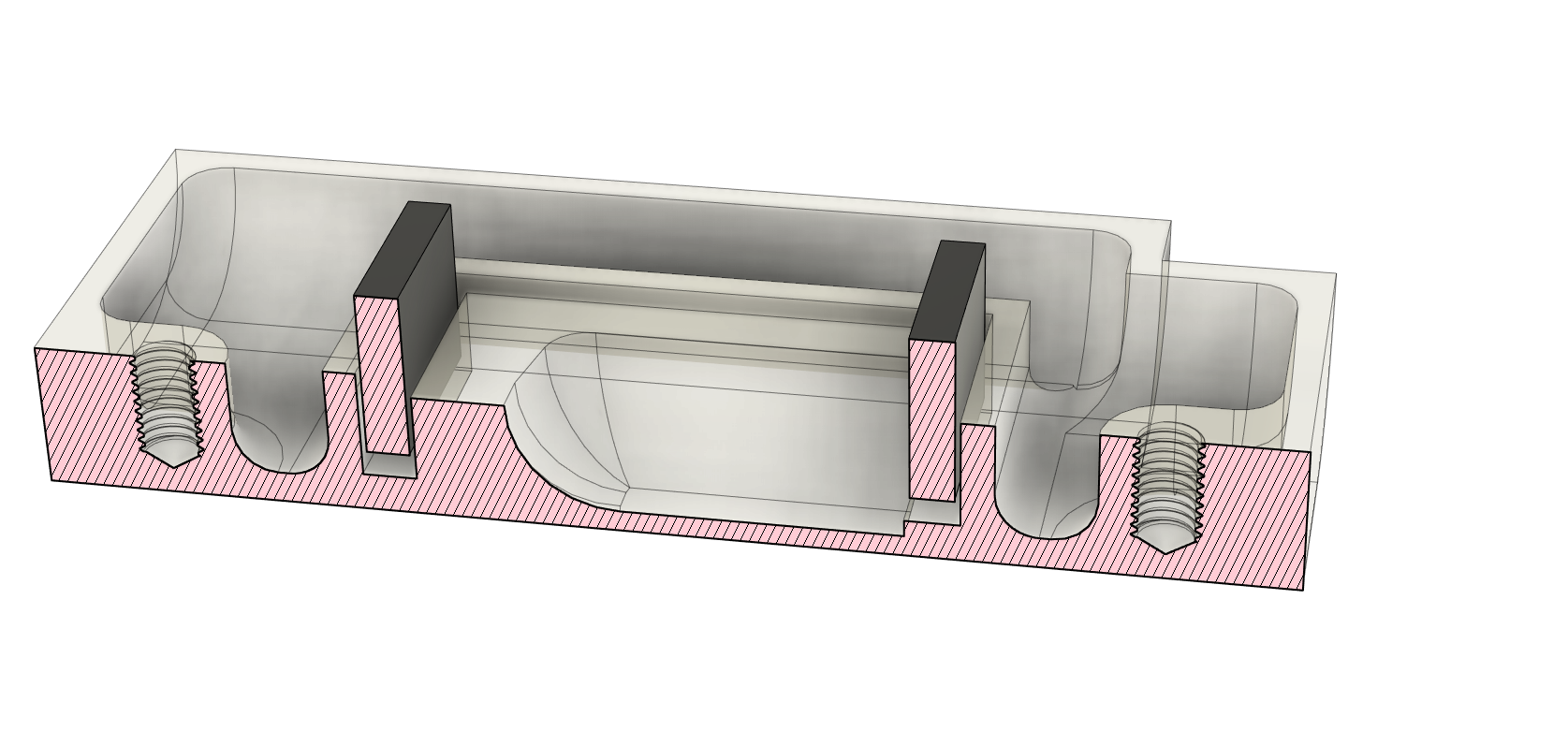

This failure became a critical learning moment. The adhesive bumpers behaved unpredictably under repeated magnetic impact, creating residue that interfered with the mechanism. To resolve this, I redesigned the internal pockets to capture rubber bumpers mechanically — eliminating adhesives, improving reliability, and ensuring longevity across thousands of cycles.

Reflection

This project reinforced the value of prototyping beyond appearance models. Small unseen details — magnet tolerances, material memory, and impact over time — defined the success of the experience. I learned how to balance precision machining with manufacturability, how to design for failure modes I couldn’t initially see, and how to maintain simplicity on the outside while managing complex constraints inside.